Fluid Power Engineering

Professional Engineering From Pneumatics to Lubrication

It’s important to take an interdisciplinary approach in this field and to include electrotechnical designs in the documentation. EPLAN has the right solution for you for these various engineering fields – combined in an integrated software environment.

An Overview of the Four Subdisciplines of Fluid Power Engineering

There are four different areas in fluid power engineering: pneumatics, hydraulics, cooling and lubrication.

Pneumatics

Pneumatics is the use of compressed air to perform work in the sense of preparing energy to act on a body. Compressed air systems are usually made up of four subsystems: compressed air generation, compressed air preparation, compressed air distribution, and then, finally, the actual application.

Hydraulics

In hydraulics, oil is used to transmit power, energy or momentum in working machines.

Cooling

Cooling can be understood as the process of removing thermal energy. If heat is extracted from solids or liquids, it occurs according to the physical principle of heat transfer.

Lubrication

Lubrication can prevent friction and wear, for instance, between two parts within a machine. A suitable lubricant or lubrication method needs to be used for this.

An Overview of the Fluid Power Engineering Tasks and Challenges

You are faced with numerous tasks and challenges in your daily fluid power engineering work. EPLAN supports you in mastering these challenges and in getting the best out of your workflows.

All Solutions for Your Fluid Power Engineering From a Single Source

Professional fluid power designs have many criteria to fulfil: symbols, circuits, tubes and piping all need to be easy to find and use. The numbering for a variety of components should occur automatically while at the same time the parts must match the resulting bill of materials. This simplifies later manufacturing and commissioning. Creating schematics should also be able to be automated, while navigating through the designs should be easy via cross-references. Take advantage of the integrated EPLAN solutions to efficiently create your fluid-technical designs.

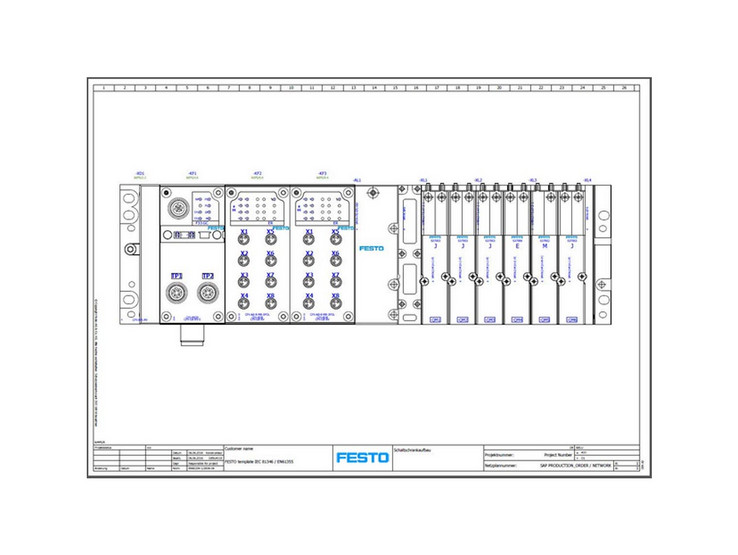

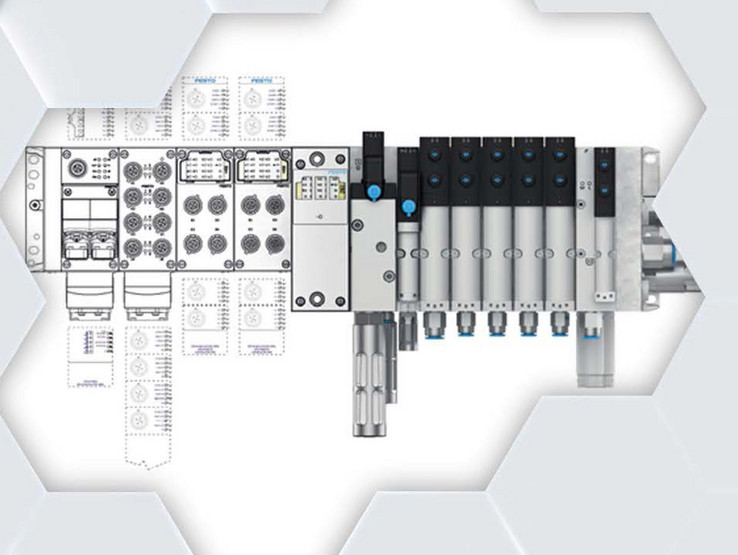

Festo Valve Terminal Configuration Based on EEC

EPLAN and Festo worked together to develop the “Smart Engineering” web service, which enables Festo customers to create a complete EPLAN Project using an app.

We’re Happy to Help!

Would you like to find out more about our solutions or are you interested in our services? Then contact us – we’re here for you!