100% Planning promises increased quality in the enclosure industry

a-on AG has implemented an integrated process for the planning and production of electrical enclosures, and uses the EPLAN Platform to do it.

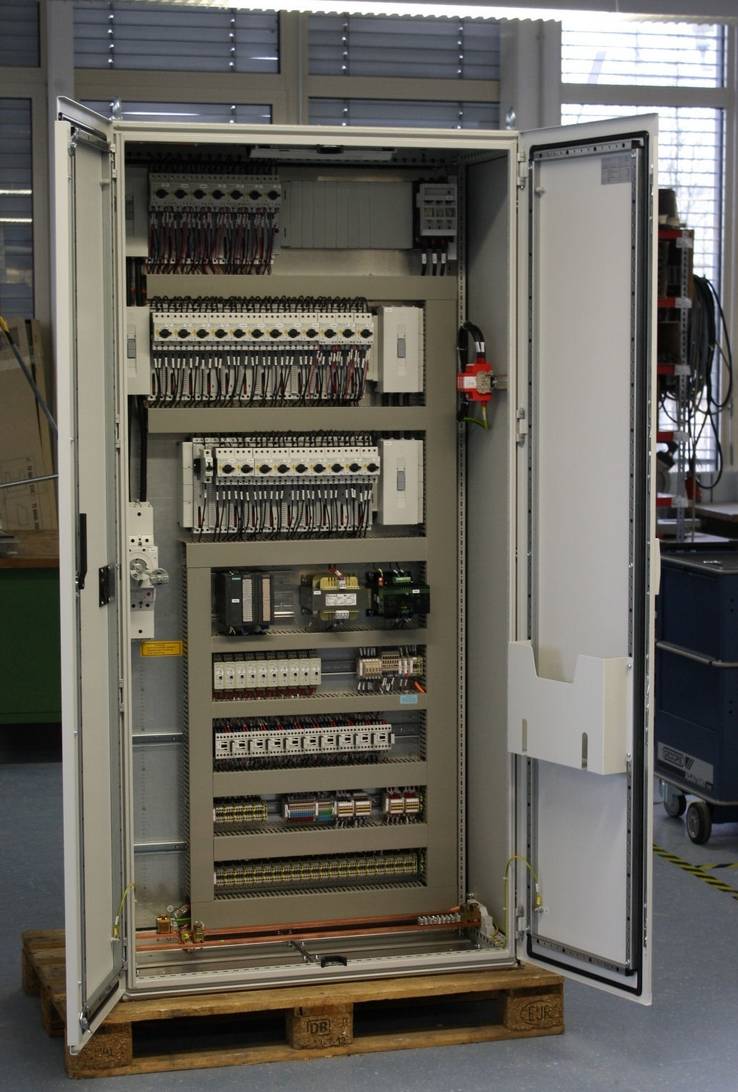

Beginning with the calculations, through the electrical design phase, on to mechanical machining, and then the pre-assembly of conductors: a-on AG, located in Neufahrn close to Munich, has implemented an integrated process for the planning and production of electrical enclosures, and uses the EPLAN Platform to do it. The initial intention actually was to optimize quality in the design process – but now their production is able to profit from 30% time savings at the same time. The company has been working since 2002 for well known international companies, from all kinds of industries, meeting their plant and special machinery engineering needs. The truly broad spectrum ranges from foodstuffs production, via wood processing, plastic technologies and automotive, through to the pharmaceutical industry. The following is one thing that all the enclosures that are designed and fabricated in Neufahrn have in common. Josef Altmann, Chairman of a-on AG: "Each unit is one of a kind." All the while, the company is able to cover a broad engineering portfolio: a-on is responsible not only for the hardware and software engineering, but often also for the design of the PLC and visualization systems, as well as the mounting of electrical equipment and commissioning of the system on-site. Goal: Integrated processes a-on has used EPLAN from the beginning and started the migration to the new platform early on. Project manager Dipl.-Ing (FH) Lorenz Huber: "The migration is not difficult, as it is facilitated by numerous automatic functions. Furthermore, the processes are improved by using the EPLAN Platform: We believe the device oriented work approach is a very good idea." We implemented the migration very early on, because we at a-on attach great importance to integrated processes. Josef Altmann: "We consider it a central criterion that distinguishes us from others competitors. Continuous processes are, in our opinion, the prerequisite for high quality and standardization in the design." Connecting E-CAD and PPS beginning in the calculation phase

This is why our work with the EPLAN Platform already begins during the calculation phase. a-on uses the software "PMS" for coupling the E-CAD system to the production planning and steering (PPS) system. Josef Altmann: "The operation of our entire company is based on E-CAD and PPS. This is why we place such emphasis on the connection between the two systems." The reciprocal exchange of data between CAD and PPS is of such great advantage during calculation, because the sales in cooperation with electrical design departments can compile the cost of a project very accurately. We achieve this by using basic assemblies, which have been stored in EPLAN. This may require a higher administrative effort up front, but it definitely pays off later. The calculations are very exact, and there will be a good data foundation for the design already in place, when the order is awarded. For instance the bill of materials for a project is available in both systems, which makes materials and quantities always transparent, and lets the designer generate an order with just the push of a button; all this thanks to the connection of EPLAN to PMS. This continuity, starting with the calculations, does not end until the project is completed and ready for billing. Data from the PPS system and the EPLAN Data Portal

a-on has consistently established an integrated flow of information, even within the electrical engineering. Special consideration has been given to the utilization of all standardization options offered in EPLAN Electric P8. A comprehensive library of components makes the work of the designers much easier. Lorenz Huber: "We have approximately 25 000 parts with part numbers and drawings stored in the system. A lot of them have been imported from the production planning system. The data and drawings of other components have been requested or downloaded from the manufacturers and converted to our standard formats. And since the EPLAN Data Portal has been put online, we can download much of the data that way." No one at a-on denies that it is no small task to import 25 000 parts into a standardized data base. But everyone involved agrees that the rewards will be well worth the effort. It facilitates standardization and the use of identical parts, which in the end will increase the design quality. Josef Altmann: "Even before migrating to the new Platform, we used automation tools that we created ourselves, in order to achieve our high quality standards and to improve process efficiency. We now have automation options we never even considered, before we had the integrated data platform." 3D layout using EPLAN Cabinet

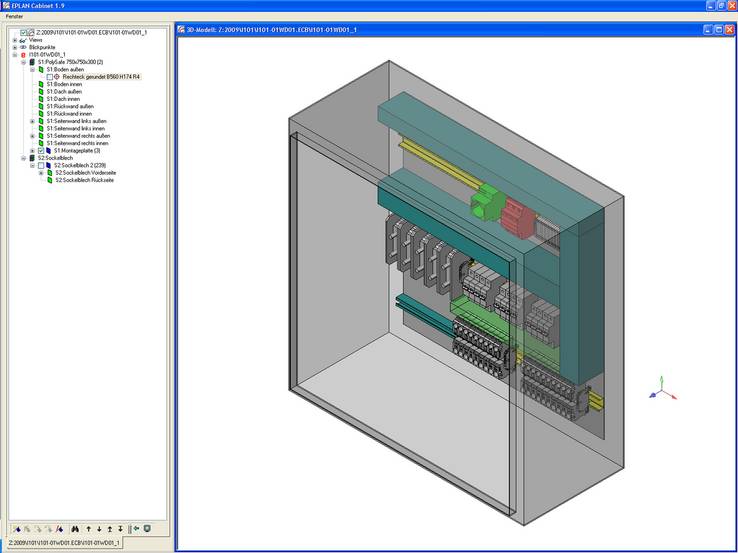

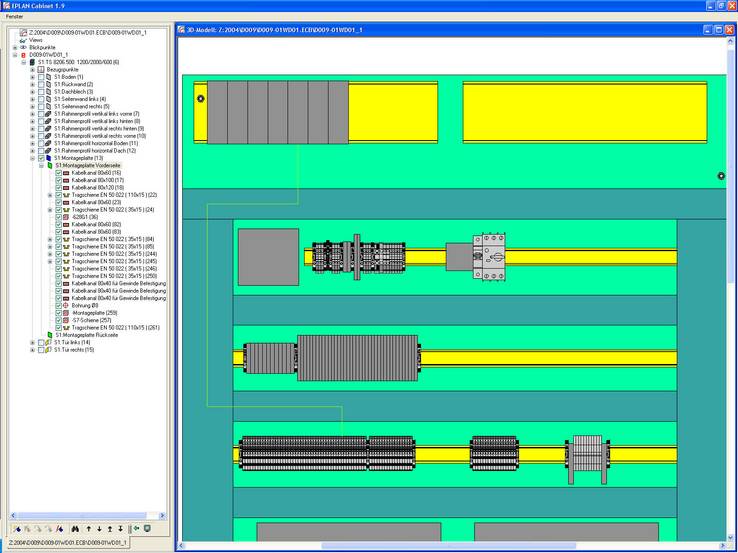

Processing of the data generated in EPLAN Electric P8 continues in EPLAN Cabinet. The system imports the electrical engineering project data. It then provides the basis for a professional 3D enclosure layout with optimized placement of components. The necessary cable lengths, as well as cutouts and drilled holes needed for the enclosure are determined automatically. EPLAN Cabinet does of course consider all individual installation requirements in the process, as well as minimum spacing and climate control. The data for Rittal's enclosure system product line can be imported directly from the RiCAD 3D product catalog. Direct connection to production So far we are still operating on the design level. But the production phase is also integrated into the information flow. The CNC data for a customized production of an enclosure can be sent directly from EPLAN Cabinet into a Steinhauer CNC system. Even conductor assemblies are by and large automated, based on the EPLAN Cabinet routing data. Lorenz Huber: "This automation makes work very easy. The wire lengths, as well as their beginning and end descriptions are already defined, and the device tags are generated automatically. The individual labeling of conductors, which is already standard in UL conform systems, can be realized easily. And since the routing data has been specified, a quasi automatic uniform placement and mounting standard for the components is the result." The quick way to an enclosure

EPLAN Cabinet provides the optimum environment for parallelizing workflows: "Using the single conductor assembly approach, production can already begin wiring the cabinet before the components have been mounted. This means that we can move up the start of production and also achieve a reliable reduction in delivery times." Another contribution to shortening the production process times is a-on's design of terminals and DIN rails in EPLAN Electric P8, which can then be ordered from vendors as pre-assembled modules, ready for installation. All these automated processes become prerequisites for a quick and error free mounting of the enclosure. Lorenz Huber: "We wire according to lists, not according to schematics. The schematic serves only for the 100% function test after mounting has been completed." Summary: Improved engineering

The responsible parties at a-on are completely satisfied with the results after the migration to EPLAN Platform. Josef Altmann: "Before, we planned maybe 80% of the enclosure, now we plan 100%. That was our goal." A side effect of all this was an improvement in our design processes: They have to work more precise - and supported by the automated processes - set up more specifications. This creates less room for variances during assembly, which is exactly what we want, since it will increase our quality. 100% Planning leads to 30% time savings

The new foundation for our design has been rated very positively: Prerequisites for the integrated, standardized processes are created with the database and through object orientation; they are at the core of a-on's new design processes. As a byproduct, an additional advantage has been achieved that wasn't even part of our focus in the beginning. Josef Altmann: "We assumed that the time needed for this method was going to be the same as before, and that the increase in quality would make all the difference. But now we are realizing that we are actually able to produce about 30% quicker. Our profits are therefore generated by the higher quality and the distinctive gain in time. We therefore have used this time of crisis well, to become better and more efficient: We can now enter the competition with an advantage and distinguish ourselves even more."

Josef Altmann, Chairman of a-on AG states: „EPLAN Platform and its integrated processes open a completely new level of automation to us“.

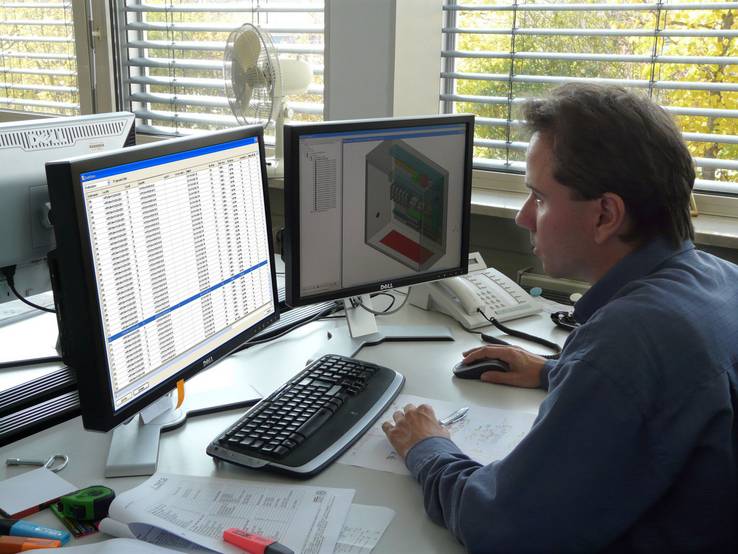

Project manager Dipl.-Ing (FH) Lorenz Huber is able to benefit from the many automated processes during the design. "The various processes can be improved by using EPLAN Platform - We think the device oriented work approach is a very good idea.“

a-on AG covers a vast range of engineering fields: Hardware and software planning for steering engineering, as well as the design of PLC control and visualization systems, the electrical systems, and on-site commissioning.