AuCom opts for automation with EPLAN and Rittal

A flying start

Can it be done in nine months? Nine months to build and supply 400 switchgear units containing soft starters for electric motors for one of the biggest infrastructure projects in Egypt – imagine doing that just two years after launching your own panel-building operations. That is no problem for AuCom Global Solutions! There was just one condition – extensive standardisation and automation.

Everything at the company in Sendenhorst, north-eastern Germany, is bursting at the seams. It’s not just the order books at AuCom that are full – the production workshops are too. Tightly bayed switchgear sits just a couple of steps from wire processing and enclosure machining equipment. Everything is crammed into the tightest of spaces. Production operations at the European headquarters of this New Zealand company currently have an overall footprint of 2,800 square metres. That is why the specialist in electronic drive technology is urgently looking for more production and warehousing space, not to mention more staff. The company already invested a seven-figure sum in the construction of a new workshop in 2022, and another workshop is due to follow this year, at a similar cost. This mid-size company is certainly on a growth trajectory. It has doubled its sales compared to 2021 and its headcount quadrupled between 2020 and 2022. In 2023, the workforce is set to top 100.

Thomas Zirk-Gunnemann, Managing Director of AuCom Global Solutions, attributes this success to a rising demand for soft starters that has been brought about by the energy revolution. “Our products have never been more relevant than they are today,” says the electrical engineer. Soft starters help to reduce the energy consumption associated with starting up large industrial motors and ease the strain on drives, power grids and power plants. According to the Managing Director, these benefits have been proven in applications such as in Qatar, where air conditioning compressors used in the World Cup 2022 stadia were fitted with AuCom soft starters, and in Egypt’s giant “New Delta” infrastructure project, where they have been used in large pumping stations for water reservoirs.

400 Units for Egypt

Another reason behind the company’s commercial success, according to Zirk-Gunnemann, is its deci¬sion to invest in automating production processes and standardising enclosure technology. “Without these developmental steps, we would have had no chance of winning the ‘New Delta’ mega project,” he explains. “We had to provide assurances we could deliver the complete project, which comprised a total of 400 switchgear units for 70 new pump stations, within nine months – and that at a time when material flows and supply chains were unstable,” points out the Managing Director. On top of this, there was tough competition from local Egyptian switchgear builders, who have much lower labour costs. “Right from day one, we knew the only way we could compete would be by putting in place automated production.” The company has eight years of experience in switchgear production.

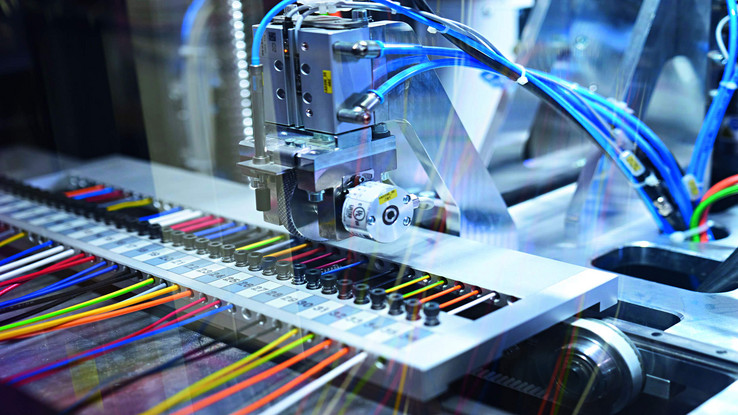

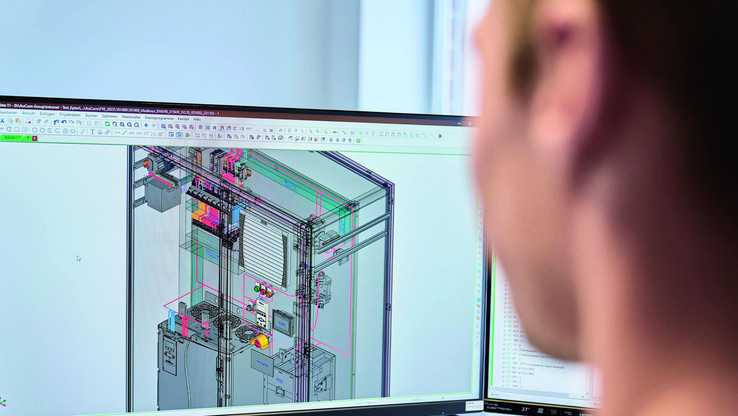

Having worked closely with suppliers and launched its own in-house panel building operations two years ago, AuCom understands the processes precisely. However, its partners were reluctant to in¬vest in automation technology. In late 2021, AuCom took matters into its own hands and invested in a fully comprehensive package of automation technol¬ogy and engineering software. “When we do some¬thing, we do it right,” declares the boss. The compa¬ny’s decision to procure the fully automated Wire Terminal wire processing system and Perforex ma¬chining centre from Rittal and to source engineering software from EPLAN paid off. “After just one year, we can say that we made the right decision and that it was exactly the right step for us in terms of being able to compete,” says Zirk-Gunnemann.

Standard model identified

One of the reasons AuCom was so successful was because it clearly defined an enclosure standard early on in the process. Once the decision had been made to market not just the safe start technology but its “packaging”, too, the company worked out which model of enclosure it should use moving forward. Thanks to a range of technical plus points and a 24-hour delivery promise, it was the VX SE free-standing enclosure from Rittal that won through as the favourite. “To be competitive, it’s essential we define a clear standard, and we’re using the Rittal standard as our own,” explains the electrical engineer. The VX SE is being used in three sizes, meaning it covers all requirements in terms of ease of assembly and cost-effective production. “It is absolutely the most logical choice of enclosure model for us and helps us cut out the most steps.”

A free-standing enclosure makes life easier

The AuCom enclosures don’t require any of the baying options that are typically used in conventional plant engineering, because the soft starter technology can only be installed in a free-standing enclosure as a standalone solution. The drive specialist doesn’t need side access to the enclosure for the purposes of assembly and fit-out either. What’s more, the com-pany wanted to save on having to unpack and fit separate side panels and dispose of all the packag¬ing material too. The VX SE covers all these needs. In contrast to bayable enclosures with a frame and removable side panels, the free-standing enclosure has an all-in-one body made from a single piece of steel sheet or stainless steel. As the side panels and roof are formed from one piece and fewer individual components are required, both ordering and assembly are far simpler and faster. Since the side panels, roof and frame are conductively connected, no additional earthing to the frame is required, delivering a further time saving.

“However, we have developed a standard that can be extended with additional options,” points out Zirk-Gunnemann. “For example, our enclosures can be fitted out in line with customer requirements to include as many system components as they need, such as rails and punched sections with additional motor circuit breakers, terminals and protection relays.” Another advantage is that, by using the VX SE, the plant engineering company can make the most of the system accessories available for the VX25 bayable enclosure series. VX compatibility for interior components is made possible by adaptor rails. This means components such as punched sections, rail systems and partial mounting plates from the VX25 can all be installed in the VX SE. As a result, the entire VX SE can be enhanced using VX25 accessories.

The full package ist just right

Although other market solutions were available for establishing automated production and creating a platform for enclosure technology, AuCom opted to hit the ‘reset’ button and start over with a whole new, all-in-one package comprising enclosure standard and automation technology. “Ultimately, we decided to get everything from the same source and build a close partnership with Rittal and EPLAN,” says Zirk-Gunnemann.

VX SE free-standing enclosure - the benefits at a glance

- Forming the side panels and roof from one piece reduces ordering and assembly outlay

- Creating the body from a single piece ensures maximum stability and torsional rigidity

- High protection category up to IP 66/ NEMA 4 or 4X

- One-piece enclosure construction ensures excellent EMC characteristics

- Engineering can be transferred 1:1 from the VX bayable enclosure to the VX SE free-standing enclosure

- The VX SE free-standing enclosure uses the same accessories platform as the VX bayable enclosure series

- Wide range of dimensions available in cluding widths up to 1,800 mm, equiva lent to up to three bayed VX enclosures

- Depths of 300 mm are ideally suited for applications where there is little space, such as for building technology