Audi reduces cycle times in engineering

Automation engineers for vehicle body construction are under considerable pressure: An increasing number of models are being launched at ever shorter intervals.

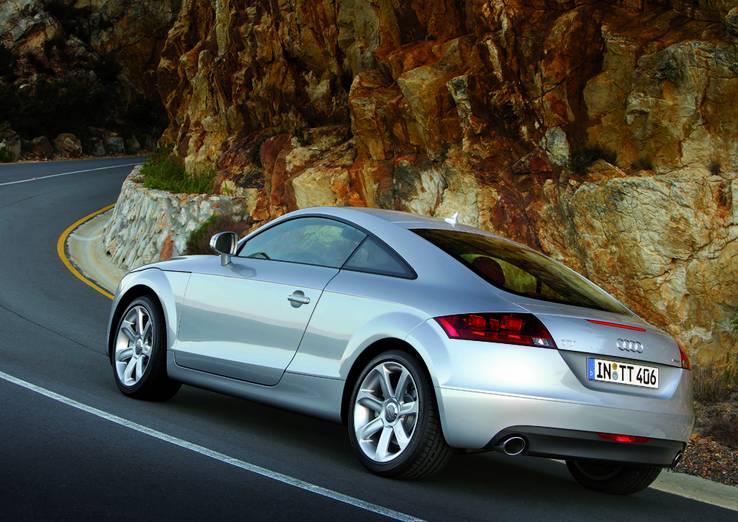

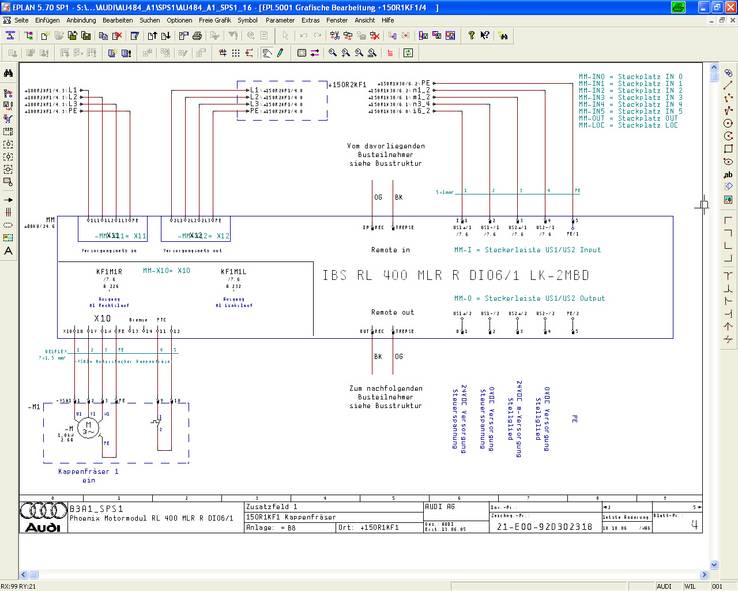

Automation engineers for vehicle body construction are under considerable pressure: An increasing number of models are being launched at ever shorter intervals. The engineering teams have less and less time to design the required manufacturing systems. In addition, the technologies used in body construction are constantly being enhanced. Here again, Audi has proven its advantage through technology: By using functional engineering with the EPLAN Engineering Center (EEC) Audi has maintained its independence from component manufactures and suppliers. Until now at Audi, mechanical design was followed sequentially by the creation of the pneumatic diagrams, then the electrical system schematics and finally the PLC programming. In functional engineering these steps are carried out concurrently and thus tremendously accelerated. In 2005 Audi Toolmaking Division placed its trust in the EPLAN Engineering Center (EEC). During the introduction of this engineering philosophy, still regarded by many companies as revolutionary, Audi realized significant savings. “Body construction lines are very complex systems that have to be developed, assembled and commissioned within a very short time. The advantages of functional engineering prove themselves in particular in such projects,” says Michael Ehrenstraßer who is responsible for the EEC team. After an initial line was commissioned as a pilot for the Audi TT in 2005, it was followed by a line for the Audi A4 and now the door line for the new Audi A1 are designed with the EEC. In the meantime, numerous PLCs and several hundred robots for various systems have been designed at Audi using the EEC. Tight schedule for complex projects

The schedules are always very tight when projects of this size are concerned. Avoiding lost time was a major reason for Audi to bring back its electrical design work, which had been outsourced before – a distinct move away from the industry trend. Nowadays, more than ever, the task is to dramatically reduce the cycle time in every project phase and furthermore to achieve an even higher degree of product maturity at an earlier point in the development phase. The introduction of the EPLAN Engineering Center made vast potentials available for Audi Toolmaking who holds several industry awards. The basic idea is for the various different engineering work to be done in parallel. In conventional working methods one step is followed by the next: First the mechanical part of the system is designed, followed by the pneumatic schematics and then the electrical schematics, until finally the control logic system is programmed. If, on the other hand, a mechatronic modular system for the hardware, the software and the pneumatics is already developed with the EEC at the beginning of the project based on the standard project, the design steps mentioned above can be carried out in parallel. Parallel design saves time and prevents errors

Similar mechanical assemblies that are technically basically the same are therefore combined with the corresponding pneumatics and electrical schematics as well as with the control software into mechatronic components and stored as a modular system. The system is designed from standardized modules that are then only configured differently in accordance with the required specification– i.e., the number of clamps or the valve grouping for a robot gripper In this functional design approach all the objects (robots, clamping circuits, control devices) and their parameters are specified mechatronically. Based on this data EEC then automatically generates the corresponding design documents, such as electrical schematics, PLC programming and pneumatic schematics, and ensures their consistency. The result is consistent documents of high quality produced for assembly, installation and commissioning. Relieving designers from non-productive work

"Today, we are able to generate our schematics for EPLAN Electric P8 completely from the EPLAN Engineering Center," notes Sebastian Lerch, electrical designer. “At the beginning creating a library element and the calculations required for schematic generation naturally takes longer than drawing a single component by hand,” says his colleague Bernhard Wagner. Once the modular system library has been completed though, the savings in time is enormous. “Predefined standard modules are kept up-to-date centrally and can be called up automatically for repetitive functions and modules,” explains pneumatics designer Thomas Prummer. Furthermore it pays off that users can work independently with the EEC without having to use additional external vendors. Audi developed the latest generation of their modular system on their own. Investment security in engineering through cutting the cord from design suppliers

At the beginning of 2005, shortly, after introducing EEC, Audi decided that PLC systems from Phoenix Contact and thus also the PC Worx programming software were to be used for the body construction line of the new Audi A4. "The changeover of the modular system to Phoenix control systems confirmed that with the EPLAN Engineering Center we made the right choice", reports Anton Habermeier, head of the plant and fixtures design in the Audi Toolmaking design center at Ingolstadt. With the Engineering Center Audi selected an open and neutral software platform into which any system can be integrated. This proved to be a fundamental advantage of the EEC after a mere three months. Within a few weeks the specialists of EPLAN and Phoenix Contact had created a solution for the integration of PC Worx program code into the EEC as well as a convenient data interface between the tools. It was therefore possible to implement the integration of new PLC programming software in a very short time, providing further impressive proof of the openness and flexibility of EPLAN Engineering Center. The switchover later from the EPLAN 5.70 E-CAE software to EPLAN Electric P8 was implemented without any major difficulties. "The time required to design the PLC systems of Phoenix Contact could be reduced markedly with the Engineering Center," reports the PLC programmer Wilhelm Hacker, adding, "the PLC basic project as well as the user interfaces of the control systems could be generated completely automatically using EEC in combination with PC Worx. Copying and typing errors are a thing of the past. I only have to carry out the programming of the system-specific workflows manually now." The most important advantage was, however, that the existing investment in the Audi-specific control knowledge for the mechatronic modular system was not lost. Only the descriptions of the control hardware as well as the templates for generating the software modules had to be adapted for the Phoenix Contact PLC´s. Gaining an edge through constant technological expansion

Together with their engineering software partners the Audi automation engineers have their sights firmly set on the goal: Configure and parameterize only with predefined mechatronic modules whenever possible. "The more the repetitive routine working steps are executed automatically, the more the engineers can spend their time developing innovative production solutions" says the head of design, Reinhardt Mielke. "Through this continuous optimization of our engineering processes, Audi ensures its decisive advantage in the time-to-market race." Copyright Audi (article may not be published without permission).