CAE system in hardest competition: Solar car circles the globe

The university's new solar car, the "SolarWorld Gran Turismo" will travel to Australia to participate in the largest and hardest long-distance race for solar vehicles.

Reach for the sun – students at Bochum University take this literally. In October, they will be entering their new solar car in the "World Solar Challenge" held in Australia. And the 3000-kilometer (1800-mile) race through the Outback is just the beginning: The car is to circumnavigate the globe for one year, powered only by the sun. A team of almost 30 members autonomously planned, designed and manufactured the racer. They glued three square meters of solar cells, developed the wheel hub motor themselves and documented the complex electronics and electrical engineering with EPLAN Electric P8. The "BO", Bochum University of Applied Sciences, makes the headlines once again: The university's new solar car, the "SolarWorld Gran Turismo" will travel to Australia to participate in the largest and hardest long-distance race for solar vehicles. Around 30 teams from around the globe will take part in the 8-day race, which starts on October 16. The BO team, which has been one of the favorites for many years, has put a lot of creativity and ingenuity into developing a car that will amaze the world. But the race in Australia is just the beginning: The SolarWorld GT is to circle the globe for 365 days, without any external source of energy. Only solar power is allowed; external sources of power are taboo. An ambitious goal, just like the team behind the new solar racer. The next stage will take place in December in New Zealand and next year the car will explore other continents. The journey will continue through the USA and Morocco, Spain and France and other European countries, and even all the way to China and Russia, a journey that demands logistical feats from the Bochum University team and their sponsor, DHL. Documented in detail

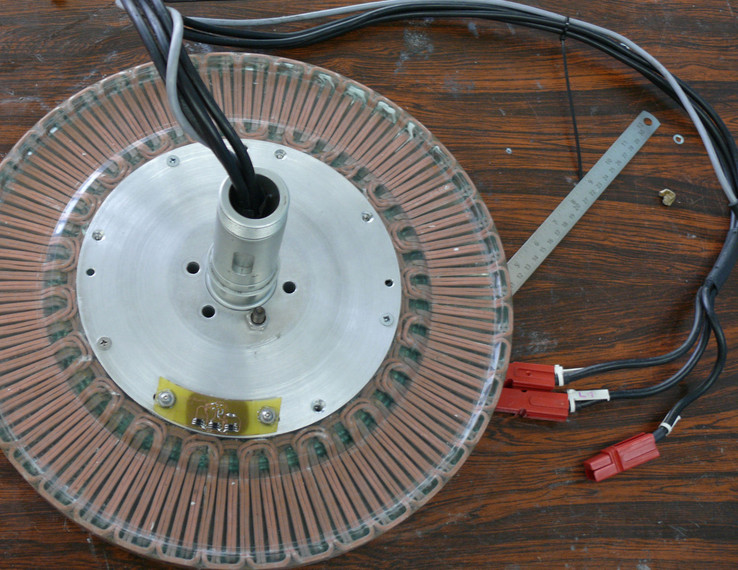

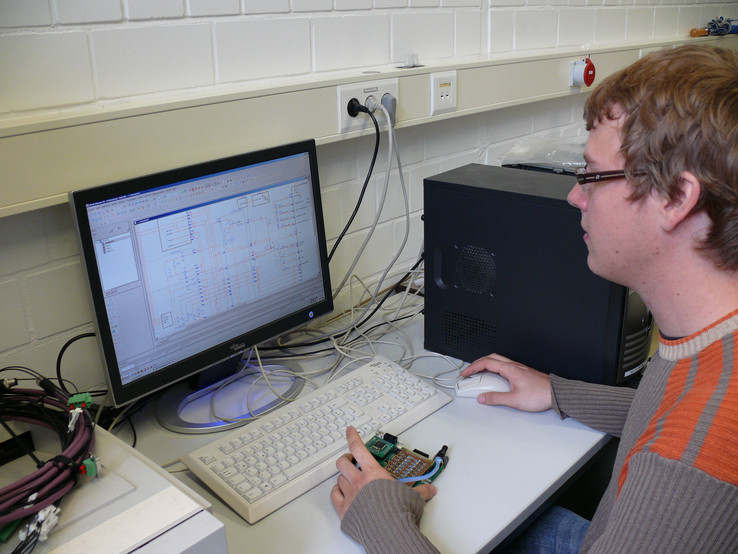

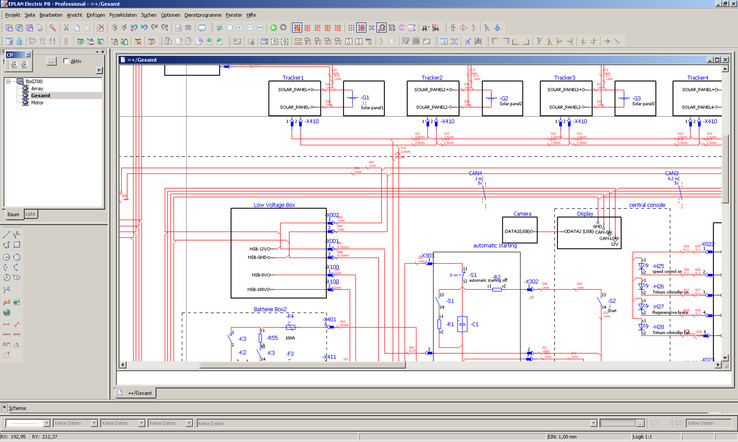

One of the people who helped develop the car is Matthias Drossel, a second semester electrical engineering student. Matthias joined the solar car team right after joining the university. It was also one of the reasons why he signed on at the "BO". His advantage: As a trained electronics technician for industrial engineering, he brought with him a lot of technical knowledge which was put to good use in the development of the car. He designed, drew and worked for many months, and meticulously documented all of the automation technology and electronics in EPLAN Electric P8. He stored electrical engineering efficiency data, created macros, routed cables and generated connection lists and terminal strip lists. He quickly came up to speed with the software and is satisfied with how smoothly everything worked. The impressive black and white result is a schematic in A0 format: The low voltage box and on-board electronics, solar generators and trackers (controllers that optimize the supply efficiency of the solar cells), motor and motor controller including all cables were planned in detail. But work doesn't stop with the design. On the contrary. The dedicated 23 year old and his fellow students routed the cables in the car, programmed the controllers, built battery blocks and glued components. The do it yourself motto demanded the total commitment of the entire team. The students even developed and built the car's wheel hub motor themselves. Hours were spent winding coils and the result astounds even experienced experts. Developed everything themselves

The body of the solar car is made of carbon fiber and designed to be extremely light and aerodynamic. The exact wind resistance values were determined during separate testing in the Audi wind tunnel in Ingolstadt and the results were used to improve energy management. The skin was laminated by hand, the solar technology was manually applied. A three square meter solar module with an efficiency of 30% was installed in the Gran Turismo – the equivalent of 935 separate cells. So-called trackers made sure that the solar module was run at the perfect operating point in accordance with the incoming sunlight. And of course the distribution of the solar fields was not left to chance, it was matched to the course of the sun. The car generates about 800 watts of energy – that's a lot, though it doesn't sound like much compared with everyday reality. This raises the question: How can a car and driver with a total weight of around 260 kg keep moving on this amount of energy? The answer is simple: The key factors are distributing the energy correctly over the driving time and the right tactic – plus the sun of course. In the long run, driving at an even speed of around 60 kilometers per hour is much smarter than leaning on the gas pedal. The car may be able to reach a speed of around 120 km/h, but this speed simply consumes too much energy. What is important is optimal energy consumption and making the right decisions when the sun is blocked by the clouds. Intelligent battery management

Since the car has to be registered for insurance reasons, EMC compatibility when using a CAN bus was tricky. The team had to ensure that no interference, whether from inside the car due to high motor currents, radio phones, sensors or batteries or from outside due to transmitter masts, for example, which interfere with the smooth operation of the car and the electronics. Another challenge was battery management, which the Bochum team solved in a convincing manner: The 470 lithium cells are measured using sensors – balancing the battery blocks makes it possible to optimally balance the charge for ideal energy distribution. A display in the central console provides information about all of the on-board electronics such as the battery levels, electricity consumption and the lighting, including the blinkers and brake lights. All of the modules used in the car, from the on-board computer to the low voltage box, were drawn and designed as black boxes. This means that if a part fails during the race, the affected module can be replaced as a single unit. This saves valuable time and ensures that faults can be quickly remedied. Goal: energy efficiency and practicality

That the car is a two-seater is a real "shock" in the positive sense for leading solar race car development teams that conventionally design for minimal weight, racing quality, and often with three wheels. But at the Solar World GT, the Bochum team is not aiming for a spot on the winner's podium – they are going for the best design award previously captured by its predecessors, "BOcruiser" and "SolarWorld No. 1". The team has designed the car so that scientific findings are transferrable to the practical building of solar cars. Stefan Spychalski, head of public relations for the project at Bochum University clarifies, "We don't want to be first, we want to be the best. Our objective was to build an energy-efficient car and, as a university, to stick to everyday reality." The top priorities are achieving a true revolution in "real" technology and the research character; the Bochum team view is that the transfer of knowledge should and must take into account practical requirements. They are now waiting for the final EMC measurements and brake test for registration, and if everything goes smoothly, then on October 16, we will hear: "Go, Gran Turismo." First the car has to be shipped by container – but who knows: Maybe the next vehicle will be an amphibious vehicle – the Bochum students are capable of anything. More information and tour diary available at: www.hs-bochum.de/solarcar.

A rakish design and a maximum speed of 120 km/h are the key features of the SolarWorld GT, the car the Bochum team has entered in the Australian race.

eeing how it feels in the driver's seat: Matthias Drossel, a second semester student and member of the solar car team, helped developed the car's electrical engineering.