A three-dimensional perspective on what's going on

With more than 30 years of experience, Franz Widhalm knows that the clearer and more future-oriented the lessons, the longer the attention span of students. The skilled toolmaker, who teaches mechatronics design at an Austrian technical college (HTL) in Waldviertel, endeavours to familiarise himself as practically as possible with the ongoing needs of the working world. His latest coup, planned for the next school year, is the virtual commissioning of digital twins. And he is casting EPLAN Harness proD in a leading design role.

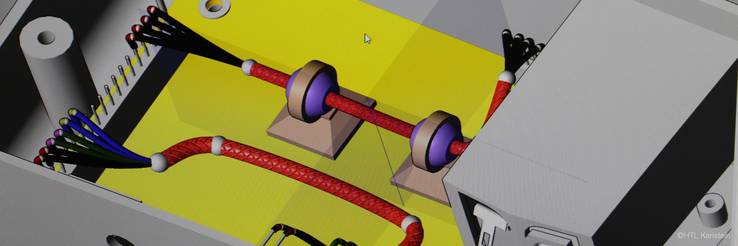

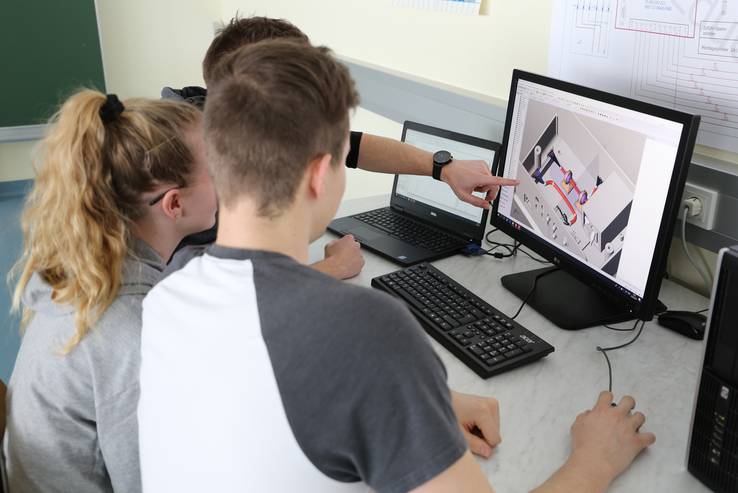

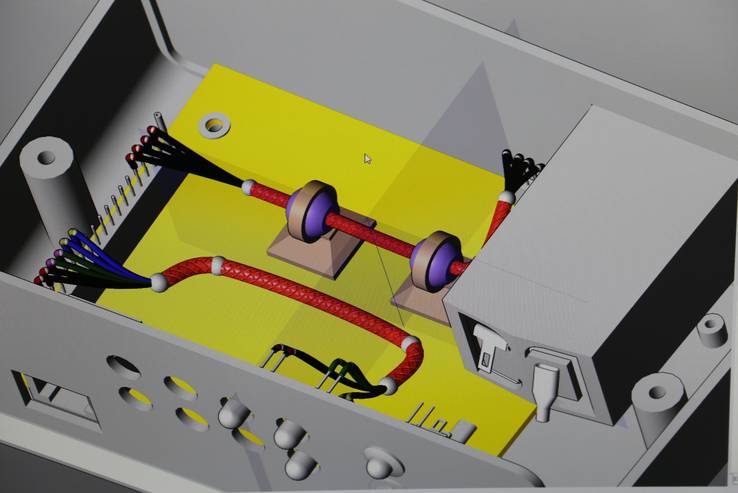

With more than 30 years of experience, Franz Widhalm knows that the clearer and more future-oriented the lessons, the longer the attention span of students. The skilled toolmaker, who teaches mechatronics design at an Austrian technical college (HTL) in Waldviertel, endeavours to familiarise himself as practically as possible with the ongoing needs of the working world. His latest coup, planned for the next school year, is the virtual commissioning of digital twins. And he is casting EPLAN Harness proD in a leading design role. Physical prototypes are a thing of yesterday. Digital twins are now increasingly being tested, refined and adapted to meet the needs of today. This is a trend that Franz Widhalm wants to include in practical training. The virtual commissioning of machines, systems and devices is therefore to be part of the curriculum at the HTL Karlstein technical college from next school year. And EPLAN Harness proD will also be playing a leading creative role. "Indirectly, students have already been demanding this software. On numerous occasions I've been asked whether it's possible to three-dimensionally display things in a circuit diagram that are difficult to discern", recalls the senior lecturer. This was the impetus for him to look more closely at EPLAN's professional tool for designing wire harnesses. Several days of basic training in Amstetten convinced him of the 3D software: "The software design exactly meets the needs of our school. It's mainly self-explanatory. Importing data from other software systems is very easy. And you start making progress within a very short time. For example, just a few mouse clicks are needed to create a true-to-scale template for production", says Franz Widhalm admiringly. The reason for this praise is that a 2D nail board drawing for automatic assembly machines can be performed just as automatically as the routing of wires and cables along pre-defined paths, the positioning of connection points, and the generation of bills of material. Plausibility checks on minimum bending radii, cross-sections, bundle diameters and much more are also included in the software.

More transparency in design

A core challenge in wire harness engineering is linking mechanical and electrical engineering. EPLAN Harness proD intelligently connects these two disciplines. Seamless communication between MCAD and ECAD systems is made possible by the necessary interfaces as well as support for neutral data format. "Defining your own plugs is also quick. Simply draw them in your usual 3D software, import them and they are instantly available in the Harness proD library for further use", says Franz Widhalm. Another feature he particularly liked in his first modelling attempts using EPLAN's harness software was that "the system automatically calculates the required cable lengths using distances between contacts". Although his students will not officially come into contact with EPLAN Harness proD until the 2018/2019 school year, some of them have had a first taste of intuitive wire harness design using the "point-and-click" method. "I'm already showing some of the advanced classes where the future is. So far the feedback has always been: Why can't we use that in class now! For our design exercises, it would be extremely helpful if we can see how individual cables and wires are to be placed in a control panel by using a realistic three-dimensional representation". This was how the senior lecturer at the HTL Karlstein college summed up the keen interest his students have for the wiring harness solution from EPLAN. Starting in autumn, this tool will be in regular use. "We were one of the first schools in the 1990s to have been working with EPLAN software in the classroom. Usually I start with a small fluid power project and then create a simple schematic. By using EPLAN Harness proD, we can now also tackle the subject of virtual commissioning in very specific terms", says Franz Widhalm. A three-dimensional representation of the design will also allow realistic testing. "Your own powers of imagination are optimally supported by this software and you can see, for example, the extent to which individual cables are bent, whether there are problems with cable length designs, and whether optimisation should or must be carried out", said the HTL lecturer indicating how the quality of a development project can be permanently improved by using EPLAN Harness proD. By Sandra Winter, free journalist, Austria

"EPLAN Harness proD exactly meets the needs of our school. This software is mainly self-explanatory. Importing data from other software systems is very easy. And you start making progress within a very short time. A true-to-scale template for production can be created with just a few mouse clicks".

Franz Widhalm, senior lecturer at the HTL Karlstein technical college