Beyond fulfilling requirements

INP North America, Inc. is an electrical engineering and services company that specializes in automation and the dual adaptation of European and American technology standards.

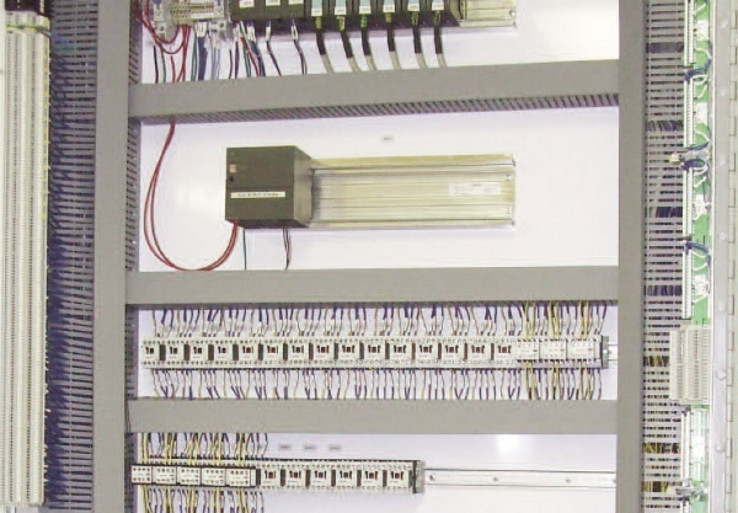

INP North America, Inc. is an electrical engineering and services company that specializes in automation and the dual adaptation of European and American technology standards. They serve multiple industries with specialized electrical projects, automation systems, energy management, electrical engineering and installation, along with emergency services. INP’s services are currently employed in the design of the Mixed Oxide (MOX) Fuel Fabrication Facility in Aiken, SC. In 1999 a contract was signed between the National Nuclear Security Administration (NNSA) and Shaw AREVA MOX Services, LLC to build a facility to be used as a part of a government program to dispose of excess weapon-grade plutonium that will be mixed with uranium oxide to create MOX pellets for fabrication of fuel rods for nuclear power plants. INP is responsible for creating the electrical design of the sintering furnace and attachments, converting the existing European electrical design to American standards, and preparing electrical drawings – they are relying on EPLAN Electric P8 to help them successfully complete the project on time. The right tool for challenging jobs

In the past, INP used AutoCAD and Promise-e as their electrical design software; however, they discovered those programs did not have the stability and quick production time needed to successfully meet engagement commitments. The programs often ended up causing more work than they eliminated. INP struggled with the lack of collaboration the programs allowed and never stayed long with one software because of this. Frank Bungartz, project manager at INP and past EPLAN user, thought it would be beneficial to explore EPLAN as an alternative CAE option. They were looking for software that had a “higher level of built-in intelligence and required less time for creating the necessary schematics,” according to Frank. Stability and tools like error checking, sharing, revision management, and standards conversion were at the top of INP's wish list. Error checking was an essential feature since all of INP’s designs for the MOX project must meet NEC, NFPA, ASME, and IEEE standards and any error could delay the project. In order to demonstrate how INP would be able to quickly create drawings that would meet their customers’ needs and increase their own internal abilities, EPLAN conducted an in-depth presentation of the software that was more than convincing. Users also underwent in-house training in order to more effectively take advantage of the software and its features. Solutions, service, and strategy

Once EPLAN was in place and functional, Frank noticed “satisfaction with the outcome of work efforts was increasing significantly.” INP team members no longer struggled with having to reproduce work that was lost when system errors occurred while trying to share work, thanks to the stability of the EPLAN Platform. There have also been notable improvements in overall build time. According to Frank, one of the most positive benefits of working with EPLAN has been the high level quality regarding the service and support received. “They’re very good. They respond quickly, and are very knowledgeable. We get real help, not the kind of call center help that takes us nowhere.” EPLAN continues to offer additional training opportunities, believing that as a knowledge base grows so does the ROI. Not only does additional training benefit the organization, but it also enhances the skills and knowledge of individual team members. Requirements of international business

The ability to convert documents and drawings to North American standards from European norms is paramount for INP. In fact, it is often a prerequisite for projects. However, the size of the documentation and software capabilities can influence what projects companies can accept, creating barriers between them and new business opportunities. Barriers are no longer an issue for INP; instead EPLAN is a gateway for future opportunities, beyond the MOX project. Andreas Droege, president and CEO of INP North America, was impressed with the increase in efficiency they have experienced since the addition of EPLAN, stating “A large part of our business is to convert European designs to US standards and regulations. EPLAN has features which enable us to perform this task. This helps us service our European customers better and more efficiently.” Strategic impact to realize large projects

INP now confidently bids on projects that in the past would have been turned down due to their size. “Today we do not shy away from larger, more complex projects, which in the past we would not have taken on,” said Frank. They now have software with the stability and speed to complete those larger projects that would have taken too long. EPLAN is now a strategic part of business; it is part of their offerings to customers. Driving growth

INP’s list of electrical engineering services and technologies are already impressive, boasting technological knowledge that extends to Siemens, Rockwell Automation, ABB, GE, and Wonderware. However, with the addition of EPLAN and its high level intelligence they have improved their production and client offerings, giving them a more confident position in the marketplace. They are stronger and more capable of quoting and managing larger engagements. “What it offers opens a lot of doors,” said Frank about EPLAN, adding “it’s now easier to offer broader services, we are absolutely more prepared.” EPLAN is not just the software used for one engagement; it is a necessary resource on which they rely to conduct business. Mr. Droege agrees, “The decision to select EPLAN as our design system was made due to our expectation that with EPLAN we would be able to manage large and complex projects on a quality level we did not have before, and at the same time improve efficiency. To date, this was the right decision.” Find out more about INP on <link http: www.inp-us.com>www.inp-us.com.