A Fitting Connection

SCHILLER grouped the fluid power design with the electrical engineering design and has been profiting from improved work processes

With the introduction of fluidPLAN (now EPLAN Fluid), SCHILLER AUTOMATION GmbH & Co. KG in Sonnenbühl grouped the fluid power design with the electrical engineering design and has been profiting since then from improved work processes. For with EPLAN 5.70 and fluidPLAN the designers utilize two CAD sys-tems that run on the same data basis. In addition, the standardization on the CAD level has also resulted in standardization on the product level: The fluid power ele-ments are now standardized more strongly. Handling and automation technology is the field of activity of SCHILLER AUTOMATION GmbH & Co. KG on the Swabian Jura. Whereby the company concentrates on two demanding and contiguous application fields: Microelectron-ics and photovoltaic. This means: If, for example, a manufacturer of power elec-tronics requires a system for bonding ceramic substrates to aluminum heat sinks or a manufacturer of solar cells requires a system to handle glass substrates or solar wafers, he is at the right address at SCHILLER AUTOMATION.

Fully automatic handling in the greatest precision

The systems are characterized by fully automatic handling via linear axes or robot technology and maximum precision. A difference of a tenth of a millimeter is often important when positioning construction elements or when loading and unloading production systems - all of which at a high speed and with extremely sensitive handling goods. With its scope of products and services, SCHILLER AUTOMATION sees itself as a competent and powerful provider for demanding products and systems. The plants are in demand worldwide. The photovoltaic in-dustry has annual growth rates of 30 to 40% and new solar factories are being erected both in Asia and in Europe and the USA. Many of them are equipped with plants and systems from SCHILLER AUTOMATION.

Intensive cooperation of the fields

Since "ready-made plants" hardly exist, CAD-supported design stands at the beginning of every project. About 35 employees work in the mechanical design team. Karl-Heinz Ruoff, head of electrical engineering design: "In electrical engi-neering design four colleagues are sufficient since a lot of work can be standard-ized here." In order to ensure smooth processing, SCHILLER AUTOMATION places great value on intensive cooperation with its customers in compliance with simultaneous engineering. The individual design fields also cooperate very closely. Thus the mechanical and electrical engineering design teams work paral-lel to a great extent. Karl-Heinz Ruoff: "As soon as the basic concept of the plant exists, our department begins with the electrical engineering design work. The time pressure leaves us no choice."

Example of a SCHILLER AUTOMATION handling system: Here wafers are bonded to printed circuit boards before being ground.

Fluid technology: From mechanical to electrical engineering design

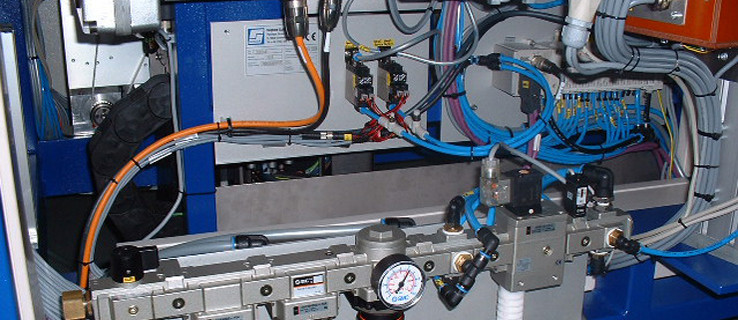

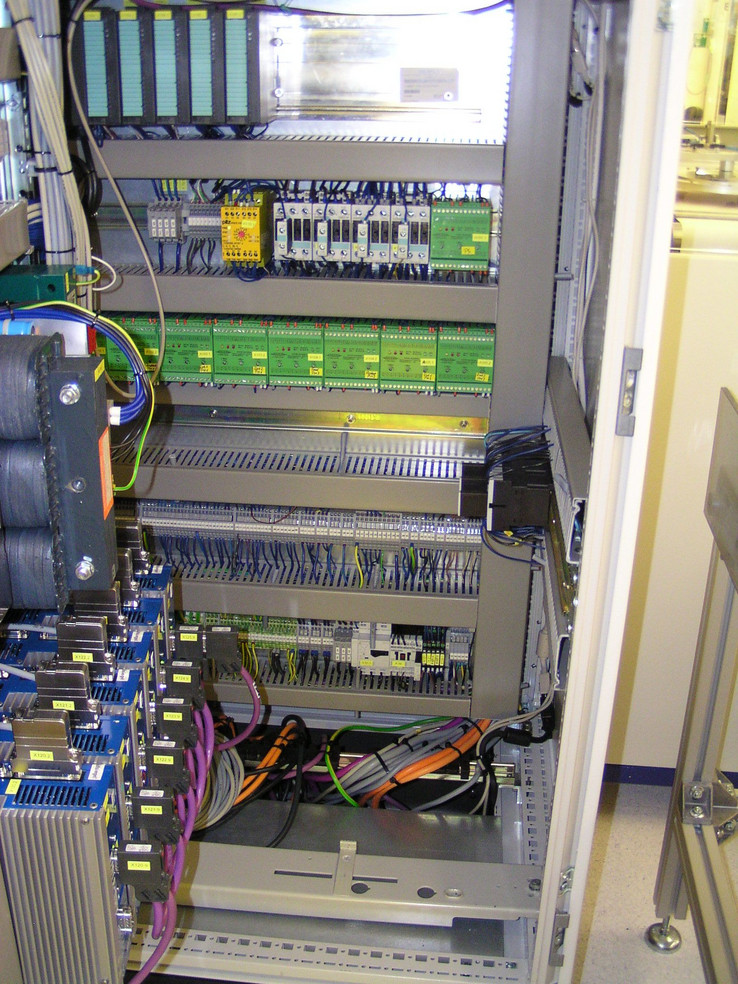

A very important interface in the cross-engineering cooperation was markedly optimized, driven by a new CAD tool. For fluid power was originally part of the mechanical engineering – and the designers allowed the erection teams a high degree of freedom. Karl-Heinz Ruoff: "The specifications were rather vague, so that there was no uniform internal company standard." This did not conform to the high quality standards in the company and, in view of the increasing importance of pneumatic equipment and – for the grippers – vacuum technology, the decision was taken four years ago to reorganize the design processes: The fluid power be-came part of the electrical engineering design. The impetus came from the use of the fluid power design software fluidPLAN (now EPLAN Fluid), one of whose first users was SCHILLER AUTOMATION. Siegfried Ruoff, designer in the electrical engineering design team: "This connection made sense from the very beginning, since the pneumatic drives and axes in our systems are almost always controlled electrically or electronically. The grippers, which are central elements in our designs, are also equipped with electro-pneumatic axes and are controlled by means of PLCs."

Two views of the same schematic

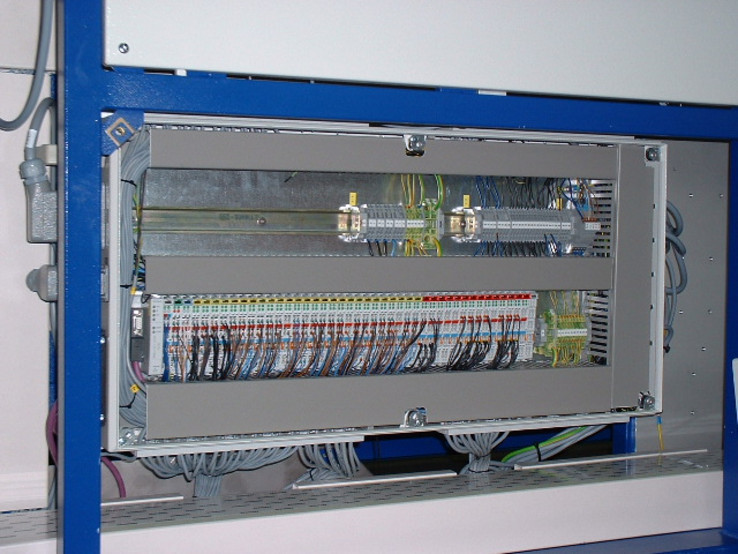

Since the electrical engineering design team uses EPLAN 5.70, it can use the same basis as the fluid power design team. Siegfried Ruoff: "In the end we use the same schematic in both disciplines. It just shows the respective view of the disci-pline currently working on it. This is furthermore an advantage because one de-signer is responsible for both disciplines. While designing one can simply change, for example, from the pneumatic element to the corresponding sensor and back." The automatic cross-references facilitate work even further.

Component libraries are used intensively

The component libraries that SCHILLER AUTOMATION created for the components of various manufacturers have furthermore made work easier. Sieg-fried Ruoff: "Our customers often specify the manufacturer to be used. The corre-sponding data and drawings are already stored in fluidPLAN – as modules that we have in part combined into macros, for example for maintenance units." The inter-faces to the component catalogs of manufacturers such as Festo, that also already exist, are therefore only required when new parts are created.

Connection to the purchase and service departments

The combination of EPLAN 5.70 and fluidPLAN is also integrated in the commercial processes: Excel bills of materials with part numbers are generated from the EPLAN data. These are processed directly by the purchase department and the components ordered. The schematics and diagrams are naturally also used by the after-sales service: The schematics for electrical engineering and fluid power, that usually encompass about 50 pages, form part of the documentation. Siegfried Ruoff: "We divide the schematics for the mounting and installation work: The pneumatics part, i.e. the fluidPLAN drawings are given to the mechani-cal fitter, while the ECAD data of EPLAN 5.70 are given to the electricians." The company is highly satisfied with this procedure. Karl-Heinz Ruoff: "The standardization results in a higher degree of transparency and the cross-references between electronic and pneumatic units simplify troubleshooting. In addition, it is also possible to carry out last-minute changes rapidly and without inconsistencies. The standardization on the CAD level has resulted in standardization on the prod-uct level, since the fluid technology has now been designed consistently and thor-oughly." These advantages will have an even greater effect when the migration to EPLAN Electric P8 and EPLAN Fluid is effected. The migration has been planned for this year and the results are being eagerly awaited: In the new EPLAN Platform the individual disciplines are interlinked even more strongly.